BIOMASS

An important source of

renewable energy!

Biomass includes a wide range of materials, including energy crops such as

switch grass and micanthus, agricultural sources such as corn husks, wood

pellets, lumbering and timbering wastes, yard wastes, construction and

demolition waste, and bio solids (treated sewage sludge). Gasification helps

recover the energy locked in these materials. Gasification can convert biomass

into electricity and products, such as ethanol, methanol, fuels, fertilizers,

and chemicals.

Biomass gasification

plants differ in several aspects from the large-scale gasification processes

typically used in our major industrial facilities such as power plants,

refineries, and chemical plants.

Feedstock

Biomass usually contains a high percentage of moisture (along with carbohydrates

and sugars). The presence of high levels of moisture in the biomass reduces the

temperature inside the gasifier, which then reduces the efficiency of the

gasifier. Therefore, many biomass gasification technologies require that the

biomass be dried to reduce the moisture content prior to feeding into the

gasifier.

Biomass can come in a range of sizes. In many biomass gasification systems, the

biomass must be processed to a uniform size or shape to feed into the gasifier

at a consistent rate and to ensure that as much of the biomass is gasified as

possible.

Air-blown Gasification

Most biomass gasification systems use air instead of oxygen for the gasification

reactions (which is typically used in large-scale industrial and power

gasification plants). Gasifiers that use oxygen require an air separation unit

to provide the gaseous/liquid oxygen; this is usually not cost-effective at the

smaller scales used in biomass gasification plants. Air-blown gasifiers use the

oxygen in the air for the gasification reactions.

Scale of plants

In general, biomass gasification plants are much smaller than the typical coal

or petroleum coke gasification plants used in the power, chemical, fertilizer

and refining industries. As such, they are less expensive to build and have a

smaller facility “footprint”. While a large industrial gasification plant may

take up 150 acres of land and process 2,500-15,000 tons per day of feedstock

(such as coal or petroleum coke), the smaller biomass plants typically process

25-200 tons of feedstock per day and take up less than 10 acres.

Biomass to Ethanol and Liquid Fuels

Currently, most ethanol in the U.S is produced from the fermentation of corn.

Vast amounts of corn (and land, water and fertilizer) are needed to produce the

ethanol. As more corn is being used, there is an increasing concern about less

corn being available for food. Gasifying biomass, such as corn stalks, husks,

and cobs, and other agricultural waste products to produce ethanol and synthetic

fuels such as diesel and jet fuel can help break this energy-food competition.

Biomass, such as wood pellets, yard and crop wastes, and “energy crops” such as

switch grass and waste from pulp and paper mills can be used to produce ethanol

and synthetic diesel. The biomass is first gasified to produce the synthetic gas

(syngas), and then converted via catalytic processes to these downstream

products.

Biomass to Power

Biomass can be used to produce electricity—either blended with traditional

feedstocks, such as coal or by itself. Nuon’s IGCC plant in Buggenum,

Netherlands blends about 30% biomass (chipped wood) with coal in their

gasification process to produce power.

Cutting Costs, Increasing Energy

Each year, municipalities spend millions of dollars collecting and disposing of

wastes, such as yard wastes (grass clippings and leaves) and construction and

demolition debris. While some municipalities compost yard wastes, this takes a

separate collection by a city—an expense many cities just can’t afford.

Yard waste and the construction and demolition debris can take up valuable

landfill space—shortening the life of a landfill. Many cities in the northeast

face a shortage of landfill space. With gasification, this material is no longer

a waste, but a feedstock for a biomass gasifier. And, instead of paying to

dispose of and manage a waste for years in a landfill, using it as a feedstock

reduces disposal costs and landfill space, and converts those wastes to power

and fuels.

Benefits of Biomass Gasification

-

Converting what would otherwise be a waste product into high value products

-

Reduced need for landfill space for disposal of solid wastes

-

Decreased methane

emissions from landfills

-

Reduced risk of groundwater contamination from landfills

-

Production of ethanol from non-food sources

Waste Gasification

|

Biomass Gasification

|

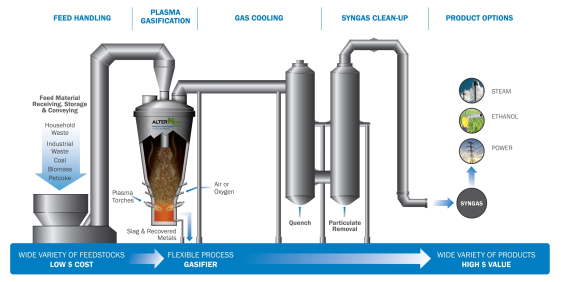

Plasma Gasification

|

Bio-fuel & Power

|

Potable Water |

Pyrolysis |

Financing |

About us |

Contact us

|