WASTE TO ENERGY TECHNOLOGY!

WPP Energy Corp, a national U.S. nonprofit

organization, promotes effective clean energy policies, develops low carbon

technology innovation strategies and works on new financial tools to stabilize

greenhouse gas emissions. WPP concentrates on climate and clean energy issues at

the state, national and international levels, as it works with diverse

stakeholders from governments as well as the private and nonprofit sectors.

WPP assists states to create and implement innovative practices and public

funding programs to advance clean energy markets and project deployment; creates

networks of U.S. and international policy makers to address climate

stabilization; advances effective, 21st century distributed innovation theories

for climate technology; develops new finance and commercialization tools; and

works to attract new investors to move clean energy technologies to the market

more quickly.

WPP work is designed to greatly accelerate the

commercialization of breakthrough low carbon technologies and to massively scale

up existing clean energy technologies as rapidly as possible to strengthen the

economy and stabilize climate change emissions. WPP is supported by major

foundations, state governments and federal agencies.

1. INTRO

-

We turn classical gasification

upside down. Conventional biogas plants turn the entire input material into

a product gas typically by means of pyrolysing the biomass into char and

gasyIying this by using air.

-

The WPP System consists of 3 main

vessels or bed reactors. The pyrolyser at the bottom, the steam reformer in

the middle and the pre-heater at the top.

2. PYROLYSER

-

In its first stage the WPP System

separates the input material by pyrolysing it into approximately 20% char

and 80% pyrogas.

-

The char is combusted into a flue

gas in order to produce necessary process heat.

3. STEAM REFORMER

-

The remaining 80% moves up into

the steam reformer. Here the pyrogas is cracked and reformed into a high

quality product gas, consisting mainly of hydrogen and carbon.

-

Steam is generated by passing the

hot product gas through a waste heat recovery boiler before it is then

quenched and cleaned.

4. STAGED

REFORMING

5. HIGH QUALITY

PRODUCT GAS

-

Unlike with common biomass

gasification processes the product gas generated in the Blue Tower is very

high in quality because it is unaffected from the flue gas from the char

combustion.

-

Common biogas plants achieve a

product gas with approximately 30-50 % calorific value, where as the Blue

Tower’s product gas achieves around 80% efficiency.

6. HEAT CARRIER

-

A key feature of the Blue Tower

is the use of a circulating bulk material as the heat carrying medium. This

ensures that the heat carrying surfaces are always clean and that the input

material such as sewage sludge maintains the required process heat.

-

This makes it easily possible to

use biomass input material which in other systems causes slogging, fouling

and corrosion.

7. HEAT PROCESS

-

The heat is transferred from the

char combustion flue gas to the inert bulk heat carrier inside a simple

moving bed reactor.

-

On the way through this process

(circulating to the top) the heat carrier first gives off its heat to the

reformer and then the pyrolyser.

-

The advantage of using a heat

carrier circuit and a motor flue gas circuit is that the different waste

heats can be collected and used to supply the collected heat where it is

needed.

8. INTELLIGENT

PROCESS - ONLY Simple Equipment Needed

-

The pyrolyser and the reformer

occur in separate gravity driven moving bed reactors. No further equipment

is mounted inside.

-

The heat carrying medium is moved

by mechanical drive and gravity.

-

At the end the Blue Tower

generates electricity out of garbage like a power station out of coal or

natural gas.

9. INPUT TO OUTPUT

EFFICIENCY RATIO

-

This highly depends on the input

material, it is also depend on the type of technology of waste process as well, a very broad estimate for separated dried household waste is 1 ton

of input generating 1.3MW - 1.7MW electric net output. The calorific value

is approx. 12 - 14 MJ/Nm3. The Blue Tower has

a gross electric efficiency of 80%.

-

In order to determine the exact

value a detailed analysis of the input material must be submitted.

If you wish a more detailed answer please fill out our

question form

or

Contact Us

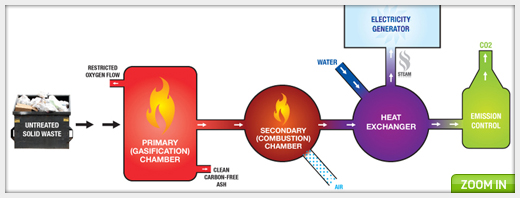

WASTE GASIFICATION

WPP Gasification

process can convert materials normally considered waste into energy and valuable

products. In the U.S. alone thousands of tons of a potential source of energy

are collected and thrown away each week. Most of the waste that we discard from

our homes and businesses every day - such as non-recyclable plastics,

construction debris, used tires, household trash, and sewage - contains energy.

WPP Gasification technology can convert the energy in all of this waste into

electric power, substitute natural gas, chemicals, transportation fuels, and

fertilizers.

PLASMA GASIFICATION

Some types of

gasification use plasma technology, which generates intense heat to initiate and

supplement the gasification reactions. Plasma gasification or plasma-assisted

gasification we use to convert carbon-containing materials to synthesis gas that

we used it to generate power and other useful products, such as transportation

fuels.

BIOMASS GASIFICATION

Biomass includes a wide

range of materials, including energy crops such as switch grass and micanthus,

agricultural sources such as corn husks, wood pellets, lumbering and timbering

wastes, yard wastes, construction and demolition waste, and biosolids (treated

sewage sludge). Gasification helps recover the energy locked in these materials.

Gasification can convert biomass into electricity and products, such as ethanol,

methanol, fuels, fertilizers, and chemicals.

BIOMASS TO BIO-FUEL

Pauwlonia Alongata Culiver Plant

In recent years, with petroleum prices heading steadily

upwards, and worldwide supplies getting tighter and tighter, we had our

scientists revisited the fermentation of sugars for the manufacturing of

biobutanol by innovative reach biomass plants that generates 10 times more than

any other plants such as a fast growing (PAC) Pauwlonia Alongata Culiver.

COMPLETE TURNKEY SOLUTION

WPP provides a complete turnkey operational power

plant under a joint venture, or (BOOT) Build Own Operate Transfer, or (BOO)

Build Own Operate, we are open for all types of combinations providing unlimited

funds from $10 Million and over $1 Billion Dollars.

More information

Talk to experts for more

information!

Waste Gasification

|

Biomass Gasification

|

Plasma Gasification

|

Hemp 2 Fuel & Power Generation

|

Financing |

About us |

Contact us

Home

| About us | Our Services |

Our Projects | |

Financing | WTE overview |

Green energy news | Request Form

|

Contact Us

|